Powertech detects equipment SF6 leaking using state of the art Optical Gas Imaging (OGI) techniques

Sulfur hexafluoride (SF6) has been listed by the Intergovernmental Panel on Climate Change (IPCC) as a greenhouse gas with a global warming potential of 23,900 times greater than that of CO2 over a 100 year period. Being a synthetic gas, it is not absorbed or destroyed naturally and it can remain active in the atmosphere for up to 3,200 years. SF6 is mainly used as a gaseous dielectric in gas insulated switchgear power installations.

Currently, electrical utilities are responsible for consuming 80% of the SF6 produced every year. It has been estimated that emissions from use of the product on a cradle-to-grave basis was as high as 15% of the amount of product used. In an effort to moderate the rise of these emissions into the atmosphere, regulations are being imposed on producers and users that include recycling and minimizing of SF6 emissions during various operation, maintenance and refill processes.

Powertech services

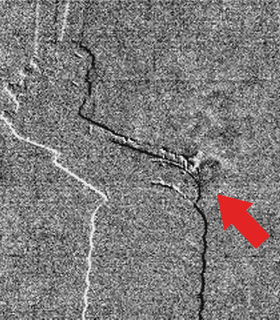

Powertech utilizes state of the art Optical Gas Imaging (OGI) techniques to identify SF6 leaks at early stage on high voltage substation switching and measuring equipment. Early detection of SF6 leaks not only reduce the emitted amount of harmful greenhouse gases but also allows for optimized maintenance actions. Our sophisticated cameras are specifically tuned to a very narrow spectral range in the order of hundreds of nanometers, and are therefore selective to the particular gas of interest. Since the energy from the gases is very weak, all camera components are optimized to provide a sufficient signal to noise ratio by maintaining the filter at a cryogenic temperature.

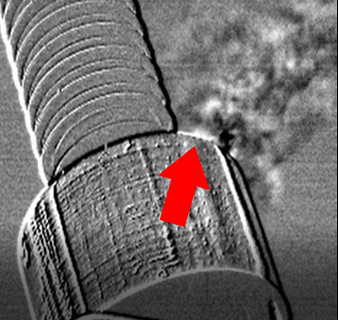

Unlike a traditional ìsnifferî, the OGI allows to survey large areas quickly and effectively and inspect spaces that are difficult to reach with non-contact measurement tools. SF6 leak detection with OGI techniques provide an additional value proposition since the observations can be conducted without equipment taking outages in an exceptionally safe manner, allowing leaks to be monitored from several meters away without any violation of limits of approach for the engineers conducting the observations.

Asset Sustain Management Benefits

By early identifying the leak location and the affected components, a significant reduction of repair downtime can be achieved. Only defective components would be replaced reducing the equipment cost (e.g. instead of replacing six bushings on a leaking circuit breaker, only the leaking one needs to be replaced). By conducting annual preventive scans to detect small SF6 leaks long before low pressure alarms are activated, reduced amounts of emissions of harmful greenhouse gases can be achieved.

Visualize SF6 and Many Other Gases

Invisible gases look like smoke through the lens of our OGI equipment, making even the smallest emissions easy to see. Powertech OGI is capable of detecting not only SF6, but several other gases including Anhydrous Ammonia (NH3), and Ethylene (C2H4).

FOR MORE INFORMATION CONTACT:

Dr. Jorge Hollman – 604.831.5148

Senior Manager & Principal Engineer

Substations Engineering Studies

Email→