Utilities continually face the need to reduce the level of contaminants in transformer oil in order to maintain performance, prevent failure, and prolong life. Maintenance crews routinely monitor build-up of contaminants in the oil such as acids, alcohols, corrosive sulfur, and moisture. Conventional decontamination methods include on-site hot oil reclamation and retrofilling. The disadvantages of these methods are that they can require taking the transformer out of service, they are costly and time consuming, they may not fully remove a contaminant, and they are not selective for specific types of contaminants.

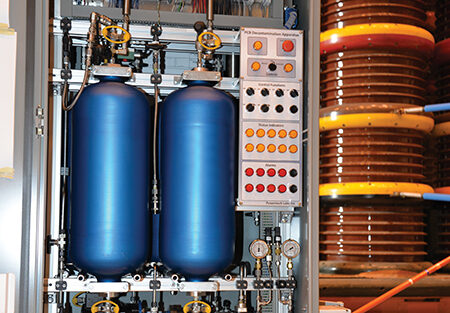

A new, efficient system, developed by Powertech Labs, enables online decontamination of mineral-based transformer oil. The system uses extraction cartridges with proprietary absorbent technology to selectively remove contaminants from the oil of an in-service power transformer.

After restoring oil properties to the level of new oil, the unit will keep the oil clean and dry at all times preventing the accumulation of other oil and paper degradation products from reaching harmful levels in the paper insulation, which will extend the life of the paper insulation and consequently the life of a transformer.

The technology offers utilities the opportunity to significantly reduce the costs associated with contaminant removal. Cost is dependent on transformer oil volume, PCB content and oil quality and estimated to be less than half the cost of retrofilling. In addition, extraction cartridges can be recharged and new cartridges easily installed by field personnel.

Decontamination units are available for purchase or as a rental service. Please contact Powertech Labs for details on purchase or rental costs for your transformers.

Key Features

- Efficiency. Transformer oil can be efficiently decontaminated to “as new” condition.

- In-Service. Removal process is plug-and-play—working on-line with in-service transformers and avoiding system shut-down.

- Lower Cost. Technology allows for lower cost to decontaminate oil and to clean insulating paper. Extration cartridges can recharged for a fee.

- Safety. Safety features incorporate inlet and outlet flow meters for leak detection, four in-line failsafe pressure and flow monitors, seven electronic failsafe switches and valves, and an optical sensor in the internal leak containment drip pan for automatic shutdown.

- Multifunctional. System is capable of performing one or more of several functions—including removal of impurities, acids, moisture, corrosive sulfur, PCBs, and de-gassing. Users can choose specific contaminants for removal.

For more information, contact John Owen, 706-897-1698, john.owen@powertechlabs.com